A. Visual Check

A1.0 Confirm warranty period applicable to the battery and ?its usage

- Warranty periods and exclusions are listed in catalogue

- A1.1 Confirm not fraudulent claim

Are warranty terms met?

- YES – Continue to A2.0

- NO – Reject Claim

A2.0 Does the battery leak?

- No – Go to A4.0

- Yes – Go to A3.0

A3.0 Can external damage be seen in the area of leak?

- No – Continue go to A3.1

- Yes – Reject Claim, Determine cause of damage

A3.1 Has the battery been overfilled by the customer

- No – Accept Claim

- Yes – Reject Claim

A4.0 Are the end walls of battery badly swollen?

- NO – Continue to section B, battery testing

- YES – Reject Claim

- Suspect Overdischarge/Overcharging

- Sulphation is not a manufacturing defect

B0. Yuasa Warranty Test

The Yuasa Warranty Test is a testing type on the Yuasa Midtronics MDX617 (P) digital tester. This test type has been developed specifically for Yuasa product in warranty situations.

YUASA MIDTRONICS MDX617 (P)

- Select ‘Yuasa Warranty Test’*

- Select application, then battery type

- Select battery standard ‘SAE’*

*IMPORTANT – Any Yuasa battery presented for warranty testing with the MDX617 (P) MUST be tested using the ‘Yuasa Warranty Test’ type and the ‘SAE’ battery standard.

- Enter CCA rating of battery (shown on label of battery) For Marine and Leisure batteries use 4 x 20hr capacity e.g. 100Ah Marine battery test @ 400A

- Press enter to test

GOOD BATTERY

- Reject Claim

- Battery is fully charged and ready to use

GOOD + RECHARGE

- Reject Claim

- Recharge Battery, then ready to use

CHARGE + RETEST

- Charge Battery, then test regain

- If same result appears after charging

- Reject Claim

- The battery has been subjected to excessive charge/discharging cycling during service

- Check vehicle electrical system for defects

- Check any non OEM fitted electrical consumers

- Check for extreme service usage, (Minicabs, ? delivery vehicles)

- Service life can be significantly reduced by electrical load/ charging imbalance and stop/start driving. These are not manufacturing defects.

REPLACE ADVISED

- Reject Claim

- Battery has lost performance due to external factors

- The battery has lost significantly its original performance

BAD CELL – REPLACE

- Accept Claim

- Battery is defective; replace battery under terms and conditions of warranty

- Note, if repeated claim from one fleet user, further investigation of battery usage is required especially if the battery is over discharging and overcharging

CHECK CONNECTION / NO DISPLAY

- Check tester leads (another battery) and ensure terminals are clean

- Switch off all electrical consumers when testing the battery if still fitted to the vehicle

- Check Battery Voltage with multimeter, if below 9.00 Volts but above 0.50 Volts then recharge/retest

- If same result appears after charging then

- Reject Claim

- The battery is unserviceable due to over discharge and sulphation

If battery Voltage = 0.50 Volts or less with multimeter, then

- Accept Claim

- Battery is defective – Replace under warranty

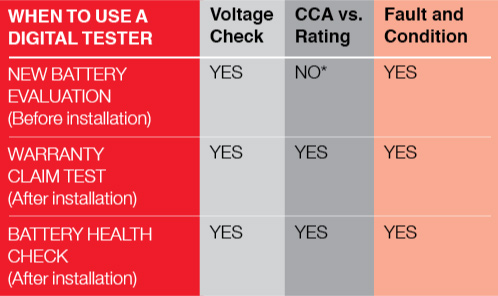

B1. Digital Testing – All Batteries

Due to an increasing number of sealed, totally maintenance free batteries in the market place, acid specific gravity readings can not always be taken, therefore we recommend a test using a recognised digital conductance tester (Midtronics/Bosch BAT121). Battery terminals should be clean to ensure a meaningful result. In the absence of specialist conductance testers, section A Visual Check and section C High Rate Test should be used.

MIDTRONICS

1. Select the SAE Testing mode (Select Warranty mode on Yuasa MDX617-627 if used, see page 368)

2. Enter 70% of the SAE Rating of the battery (shown on the label of battery).

a. For Marine and Leisure Batteries use 4 x 20hr capacity e.g. 100Ah Marine battery test @ 400A

3. Continue to Test

a. For earlier 415 model, there is no automatic temperature compensation, every °C drop below 20°C equates to approximately 4A loss in Midtronic reading

GOOD BATTERY

- Reject Claim

- Battery is fully charged and ready to use

GOOD + RECHARGE

- Reject Claim

- Recharge Battery, then ready to use

CHARGE + RETEST

- Charge Battery, then test regain

- If same result appears after charging

- Reject Claim

- The battery has been subjected to excessive charge / discharging cycling during service

- Check vehicle electrical system for defects

- Check any non OEM fitted electrical consumers

- Check for extreme service usage, (Minicabs, ? delivery vehicles)

- Service life can be significantly reduced by electrical load/charging imbalance and stop/start driving

These are not manufacturing defects.

REPLACE BATTERY

- Reject Claim

- Battery has lost performance due to external factors

- The battery has lost significantly its original performance

- The battery has lost performance due to external factors, such as overcharging, undercharging, deep cycling, wear and tear

These are not manufacturing defects.

BAD CELL BATTERY

- Accept Claim

- Battery is defective, replace battery under terms and conditions of warranty

- Note, if repeated claim from one fleet user, further investigation of battery usage is required especially if the battery is overdischarging and overcharging

CHECK CONNECTION/NO DISPLAY

- Check tester leads (another battery) and ensure terminals ?are clean

- Switch off all electrical consumers when testing the battery if still fitted to vehicle

- Check Battery Voltage with multimeter, if below 9.00 Volts but above 0.50 Volts then recharge/retest

- If same result appears after charging then

- Reject Claim

- The battery is unserviceable due to over discharge ?and sulphation

If battery Voltage = 0.50 Volts or less with multimeter, then

- Accept Claim

- Battery is defective – Replace under warranty

BOSCH BAT121/131

1. Select the SAE or EN1 mode

2. ?Enter 65% of the Rating of the battery (shown on the label of the battery).

a. For Marine and Leisure Batteries use 90% of (4 x 20 hour capacity shown on top label of battery)

3. Continue to Test

a. Adjust for temperature

b. Note Reading between Bosch and Midtronic tester vary significantly hence recommended use of 90% rating for Bosch tester

GOOD BATTERY

- Reject Claim

- Battery is fully charged and ready to use

GOOD + RECHARGE

- Reject Claim

- Recharge Battery, then ready to use

CHARGE + RETEST

- Charge Battery, then test regain

- If same result appears after charging

- Reject Claim

- The battery has been subjected to excessive charge / discharging cycling during service.

- Check vehicle electrical system for defects

- Check any non OEM fitted electrical consumers

- Check for extreme service usage, (Minicabs, ? delivery vehicles)

- Service life can be significantly reduced by electrical load/charging imbalance and stop/start driving

These are not manufacturing defects.

REPLACE BATTERY/UNSERVICEABLE

- Reject Claim

- Battery has lost performance due to external factors

- The battery has lost significantly its original performance

- The battery has lost performance due to external factors, such as overcharging, undercharging, deep cycling, wear and tear

These are not manufacturing defects.

REPLACE BATTERY/CELL SHORT CIRCUIT

- Accept Claim

- Battery is defective, replace battery under terms and conditions of warranty

- Note, if repeated claim from one fleet user, further investigation of battery usage required especially if the battery is overdischarging and overcharging

TEST NOT POSSIBLE/CHECK CONNECTION

- Check tester leads (another battery) and ensure terminals are clean

- Switch off all electrical consumers when testing the battery if still fitted to the vehicle

- Check Battery Voltage with multimeter, if Voltage > 0.50 Volts. Disconnect Battery from vehicle then recharge/retest

NO DISPLAY

- Confirm Battery Voltage = 0.50 Volts or less with multimeter

- Accept Claim

B2. Specific Acid Gravity Testing – Battery with removable vent plugs

In a good battery the specific acid gravity (sg) should be the same in all cells. The expected tolerance between all 6 cells is 0.03g/cc (e.g. range of 1.26g/cc to 1.29g/cc).

- After charging a flat battery, insufficient charging may lead to insufficient mixing of acid above the plates. Using a multimeter, confirm the stabilised measured voltage matches the voltage calculated from the specific acid gravity measurement

- (Average measured specific acid gravity +0.84) x 6 should be equal to the measured voltage using a digital multimeter. If not, continue to recharge the battery

Acid Gravity 15°C 1.25-1.28 g/cc Battery Condition Fully Charged – Proceed with Test

Acid Gravity 15°C 1.20-1.25g/cc Battery partially charged – Charge before proceeding

Acid Gravity 15°C less than 1.20g/cc Battery low state of charge – charge immediately, the battery may or may not recover, subject to period battery left in this low state of charge

B2.1 Has one cell a lower acid gravity than others?

- Example 1.26, 1.25, 1.25, 1.26, 1.26, 1.15

- YES – Accept Claim

- Replace Battery under terms and conditions of warranty

- NO

- Continue to B2.2

B2.2 Is the electrolyte dark brown and/or evidence of excessive water consumption/topping up?

- YES – Reject Claim

- Damaged caused by overcharging

This is not a manufacturing fault. Check voltage regulator on vehicle.

- Damaged caused by overcharging

- NO

- Continue to B2.3

B2.3 If the specific acid gravity is the same in all cells but reading lower than 1.25g/cc, charge the battery.

- Is the battery charge acceptance able to achieve the recommended recharge current, (see catalogue) after 1-2 hours after commencing charging?

- NO – Reject Claim

- Battery badly sulphated due to deep discharging or undercharging

This is not a manufacturing fault. Check the vehicle charging system (fan belt tension, alternator regulator).

- Battery badly sulphated due to deep discharging or undercharging

- YES

- Complete the recommended recharge

- Continue to B2.4

B2.4 Is the specific acid gravity the same in all cells and above 1.25g/cc?

- NO

- All cells even but less than 1.24g/cc, then extend recharge by 6 hours

- If one cell has a lower specific acid gravity than others go back to B2.1

- YES

- Continue to C High Rate Discharge Testing

C. High Rate Discharge Testing

This test should only be carried out if battery voltage > 12.5V, otherwise recharge battery according to recommended recharge rates and period (see catalogue)

C1.0 Is the High Rate Discharge Test indicating GOOD Battery?

- YES

- Reject Claim

- NO

- Continue to C2.0

C2.0 Was end of Discharge test showing immediate drop to 0 Volts?

- YES

- Accept Claim (subject to no visual damage to battery)

Manufacturing Defect – Internal Connection break. Replace battery under terms and conditions of warranty.

- Accept Claim (subject to no visual damage to battery)

- NO – End of test showed 1.0 Volts to 9.0 Volts

- Reject Claim

This is not a manufacturing defect.

Service deterioration.

* See Digital Conductance Testers explained

Note: If the battery has been identified as over discharged, then attempt to recharge, however if the battery has been left in low state of charge for period of time, recovery is less likely due to the deposition of large crystal sulphate formation in the plates and in the separators which will lead to grid damage and soft short circuits in the separator during attempts to recharge.